Deformulation

Deformulation can also be referred to as reverse engineering or competitor product analysis.

Using a variety of analytical methods, our lab identifies and quantifies individual components within a material. This process is customized to your project’s unique requirements. The scope of testing can be as simple as determining the type of polymer or as detailed as identifying and quantifying low wt% additives present for custom compounding. Most projects fall into one of two categories: 1.) Resin identification and general characterization methods listed on a technical data sheet to source a replacement resin or derisk supply chains. 2.) Identification and semi-quantitative wt% of each additive based on various chromatography screening methods for custom compounding or competitor analysis. Both categories will commonly include NMR for copolymer determination and ratio for olefin and ABS resins.

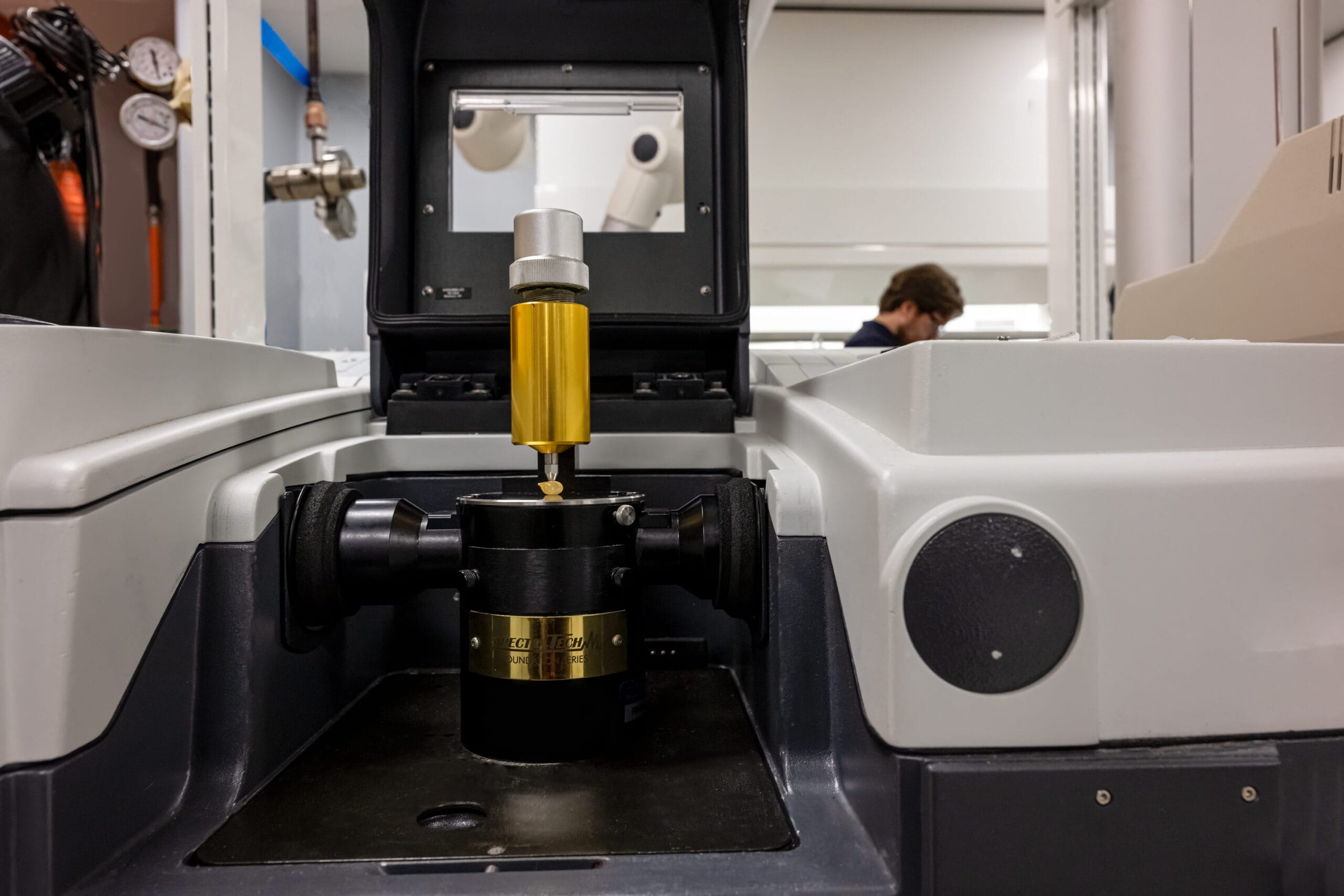

Resin identification and general characterization typically includes identification by FT-IR and/or DSC, measurement of tensile, impact, and flexural physical properties, and various thermal characteristics determined by melt flow index, TGA, DSC, or DMA.

Deformulation projects focused on additives involve multiple steps. In the first stage of the project, various chromatography screening methods are used to identify compounds present and provide semi-quantitative concentrations. If true quantitative analysis is required, the chromatography instruments are calibrated specifically for the additives of interest for the second stage of testing.

A full deformulation includes a combination of methods listed above but is always customized to your specific material and requirements.