Thermal

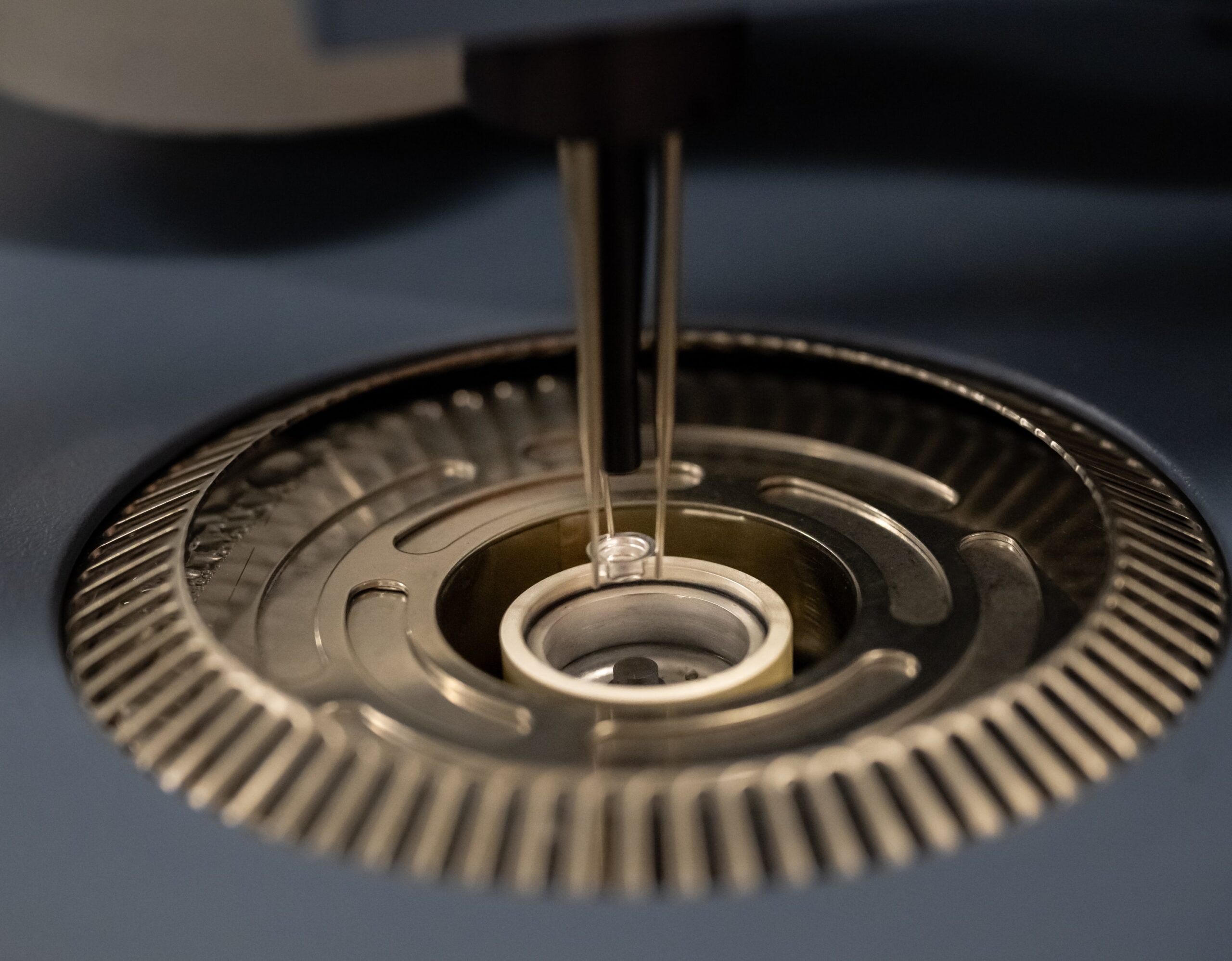

Thermogravimetric Analysis (TGA) continuously monitors the mass of a sample during isothermal or dynamic temperature scans in an air, nitrogen, oxygen, or specialty atmosphere.

The resulting graph of mass versus temperature reveals the evaporation of materials, decomposition of polymers, and the presence of fillers and carbon black.

TGA is a useful tool for examining thermal stability of materials as well as for compositional information. The temperature at which weight loss occurs is important for understanding how a material will hold up under extreme conditions. By exploiting various atmospheres within the instrument, it’s possible to determine how much carbon black and inorganic filler are present in a sample.

Approaches

The thermogravimetric analyzer operates at ambient pressure with a selected gas. Alternatively, the gas can be changed during an analysis. A gas switch is commonly used during an analysis of carbon black filled rubber materials so that decomposition of the rubber can be distinguished from decomposition of the carbon black.

The TGA operates at and above ambient temperature to an upper limit of 1000 °C. The analyzer can detect weight changes of approximately 1 millionth of a gram.

Sample Considerations

A sample for Thermogravimetric Analysis must be a solid or a liquid. The sample is confined within an inert sample pan. Typical polymer-based samples weigh 10 to 20 milligrams whereas inorganic and metal samples may weigh as high as 40 to 50 milligrams. Thermogravimetric Analysis is used to evaluate every type of plastic and rubber material. Commonly analyzed materials include:

- PVC insulation materials

Contact us to talk through your specific sample considerations.

Experience

Work We’ve Done:

- Rubber seals

- Vinyl fabrics

- Automotive components