Polymer Characterization

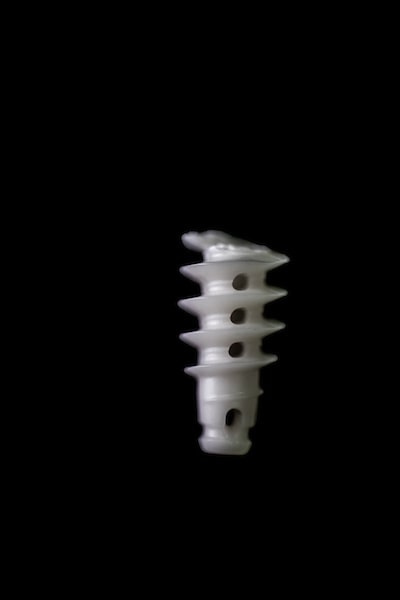

ISO 15814 is used to determine the chemical and mechanical changes in polylactide-based polymer surgical implants.

This analysis is used to assess the changes in properties in vitro and cannot be used to definitely determine in vivo conditions. The approach to this testing is twofold: chemical degradation testing and also mechanical testing.

In vitro Degradation

Samples are typically aged completely immersed in a buffer solution with a pH of 7.4 and an appropriate volume for the specimen mass and size. The samples are aged at a temperature of 37°C.

During aging, pH measurements are performed periodically to ensure the samples remain at a pH 7.4. Adjustments are made as needed.

Time Points

For materials that are intended to degrade over a short time period, the time points for analysis are between 0 and 26 weeks. For materials that are intended to degrade over a longer period of time the time points range between 0 and 52 weeks. At least 7 test periods should be assessed.

The appearance at each time point is noted and ultimately reported. For statistical analysis, six replicates must be tested at each time point. If statistical analysis is not required then the recommendation, according to ISO 15814, is for three samples to be tested at each time point.

Common tests at each time point include dilute solution viscosity and mass loss, although the exact test plan is dependent on the application of the part.

Mechanical Testing

Mechanical testing may be performed to simulate the intended loading condition of the device. When selecting the method, the form of the sample should be considered. For example, is the material a film, foil, sheet, fiber, textile, or rigid part?

We also have the capability to create custom test fixtures to assure the mechanical testing simulates actual use conditions.

Sample Considerations

Contact an expert to learn more about our sample considerations and many years’ experience in Implant Analysis:

ISO 15814 Testing