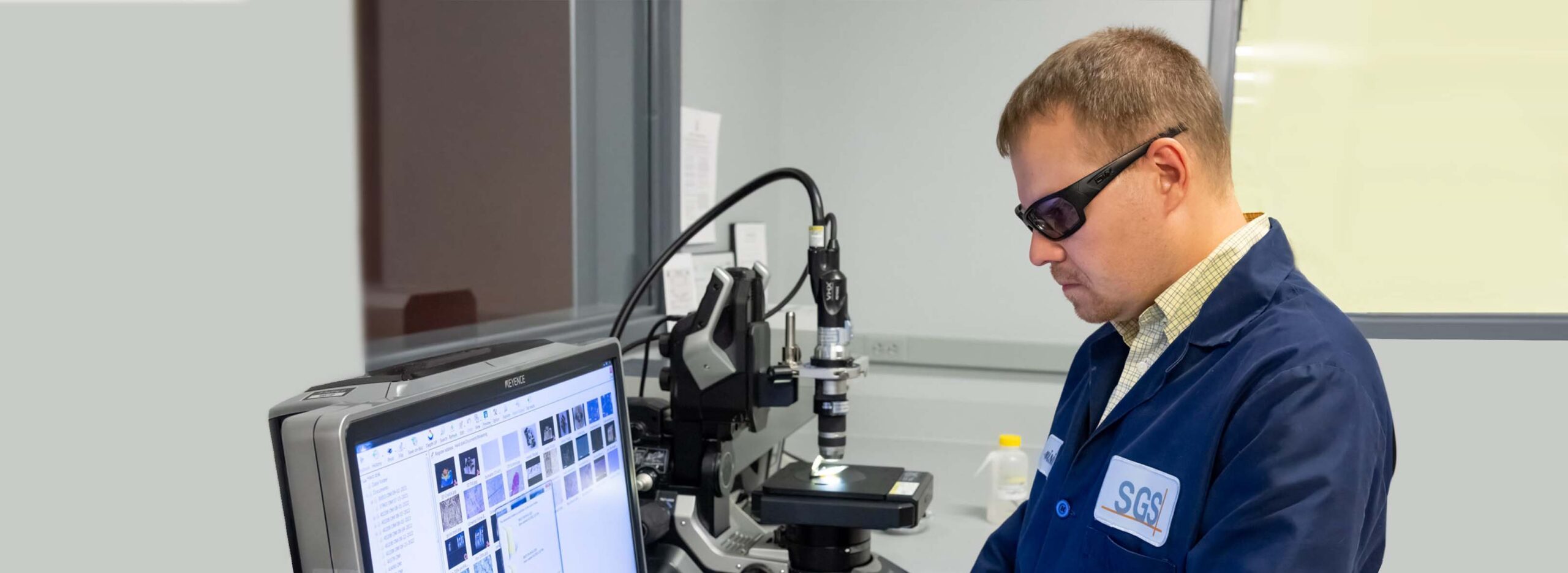

Microscopy

We have the experience, equipment, and expertise to provide the contamination analysis solutions you require.

Contamination in products can cause a variety of problems which can include failure of a product, undesirable aesthetics, or failure of quality control. Each of these consequences can cause a manufacturer to not only lose money on a single part, but to also take losses for entire batches and lots of products. Therefore, performing the proper contamination analysis, with the required equipment and expertise is critical.

Approaches

Fourier Transform Infrared Spectroscopy (FTIR) is a powerful technique which can identify an array of contaminants, usually consisting of organic material. The contaminants can be in virtually any form (solid, liquid, or gas) and can be comparably small. A contaminant is tested and compared to our impressive and extensive database of known compounds

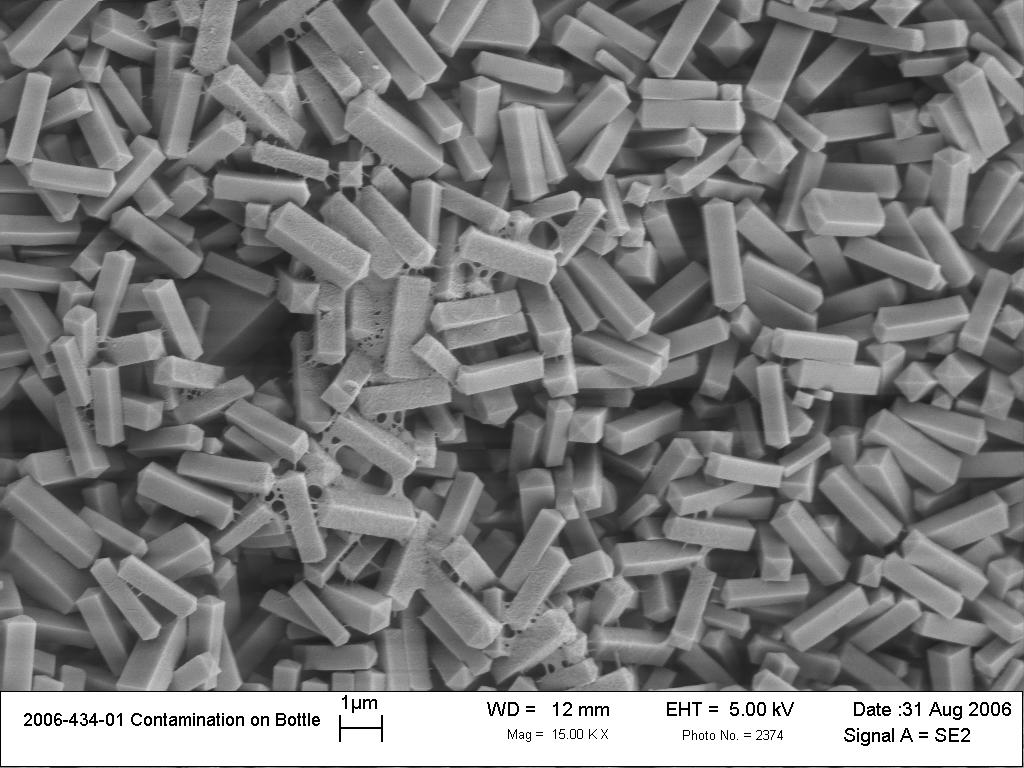

Scanning Electron Microscopy with Energy Dispersive Spectroscopy (SEM-EDS) is another fundamental technique in the identification of contaminants. In contrast to the FTIR, inorganic contaminants and defects are most applicable to this technique. The SEM can analyze a defect by shape and size and pinpoint key locations where a contaminant is located. The EDS can further analyze the contaminant and give the elemental composition of the defect.

Optical Microscopy (OM) is particularly important to use when contaminants and defects are identified by color. It is also an essential tool when scanning a sample for contaminants for subsequent contamination analysis, such as FTIR and SEM/EDS.

X-Ray photoelectron Spectroscopy (XPS) is used for contaminants that are extremely thin and found on coatings and surfaces. The very shallow penetration depth of this method makes this technique particularly useful when analyzing samples for surface oxidation, and other characteristics unique to the sample surface.

Gas Chromatography with Mass-Spectroscopy (GC-MS) is particularly useful when identifying volatile and semi-volatile contaminants found on the surface of a product. The product is swabbed and then tested with chromatogram and spectrum is generated. The results from the spectra are compared to our advanced GC-MS library to give an accurate identification of the contaminant.

Sample Considerations

The sample requirements will vary based on the testing plan needed for your project.

Contact an expert to talk through your specific sample considerations for your contaminant analysis needs.

Experience

Work We’ve Done:

- Syringes and other medical devices

- Painted products

- Wood and decks

- Plastic and metal pipes

- O-rings and gaskets

- Powders

- Blades

- Strange liquid residues

- Mattress and other foam defects

- Many consumer and industrial products

- Thermoset or thermoplastic materials

- Injection molded plastic parts

- Cross-sectioned bullets