Physical

The Rockwell hardness testing technique calculates the hardness of a metal by measuring the depth an indenter travels into a metal, after a known load is applied.

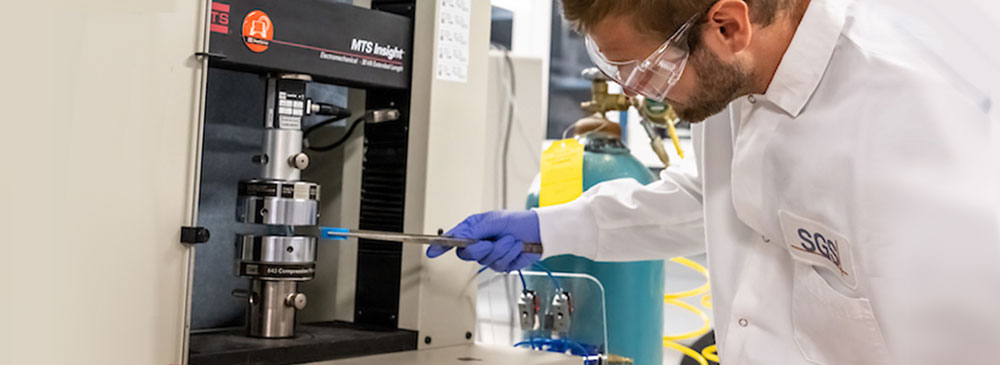

Rockwell hardness is a common hardness measurement technique whereby the hardness of a metal is calculated by measuring the depth an indenter travels into the metal after a known load has been applied. There are several Rockwell hardness scales which utilize different indenters and loads, and we are equipped to measure samples using the Rockwell B and Rockwell C scales.

Approaches

Rockwell B measures softer metals such as brasses.

Rockwell C is used for harder metals such as steels.

When conducting Rockwell Hardness tests most metals are tested several times, and the average hardness value as well as the standard deviation are reported.

Hardness can vary across a sample, especially samples which have different thermal profiles such as welds, or samples which have experienced surface hardening treatments.

In metallic materials, the yield strength can often be approximated from a hardness measurement.

For Rockwell C Hardness testing, SGS PSI conforms to ASTM E18.

Sample Considerations

Samples usually have to be flat, with a thickness of at least 10 times the depth of penetration by the indenter. If samples are not flat, they can be prepared by SGS PSI using standard metallographic techniques.

Contact an expert to discuss your Rockwell Hardness testing needs and associated sample considerations.

Experience

We’ve tested automotive parts, heavy machinery tooling, and even bullets with Rockwell Hardness Testing.