Physical & Mechanical Testing

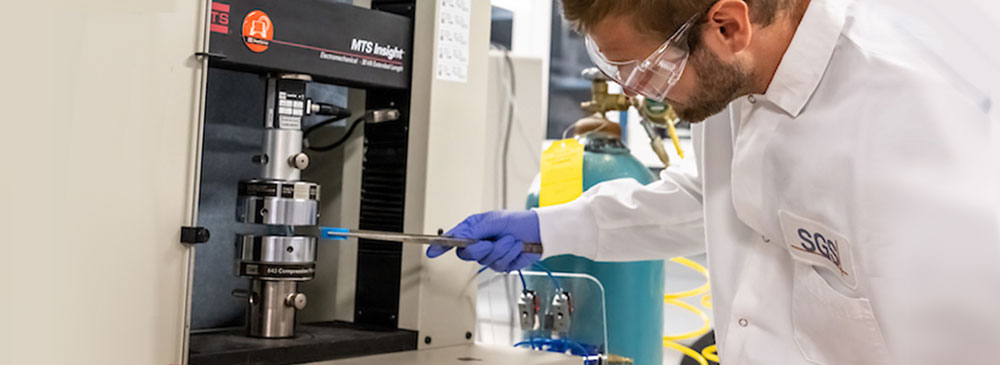

Physical & Mechanical Testing Services

Verifying polymetric materials through physical and mechanical testing will ensure your product meets the performance standards required for their applications. It is especially useful for predicting how suitable a polymer is for a specific application or to ensure a current lot of resin is within specification.

Physical and mechanical testing methods may include determining its softening point, confirming a material’s density, or evaluating its tensile strength. These properties are crucial for selecting the appropriate resins or ensuring that the delivered resin meets the specified purchase requirements.

Custom and Standard Testing Methods for Plastics and Polymers

At SGS PSI we offer both standard polymer test methods and customized testing designed to meet your product’s unique requirements. Custom testing can range from developing specialized methods testing of resorbable medical devices to impact testing of an injection molded part in its final use form.

Standard testing methods include:

- Tensile Strength and Modulus (ASTM D638, D412, D882, ISO 527)

- Flexural Strength and Modulus (ASTM D790)

- Compression (ASTM D695)

- Izod Impact (ASTM D256, D4812, ISO 180)

- Charpy Impact (ASTM D6110, ISO 179)

- Tear Strength (ASTM D1004)

- Lap Shear (ASTM D1002)

- Density/Specific Gravity (ASTM D792, D1505)

- Durometer Hardness (ASTM D2240)

- Compression Set (ASTM D395)

- Coefficient of Friction (ASTM D1894)

- Dimensional Analysis Ash Content (ASTM D5630)

- Heat Deflection Temperature (ASTM D648)

- Vicat Softening Point (ASTM D1525)

- Capillary Rheology (ASTM D3835)

- Injection molding of ASTM and ISO test specimens

Contact an expert to learn more about our polymer physical and mechanical testing services.