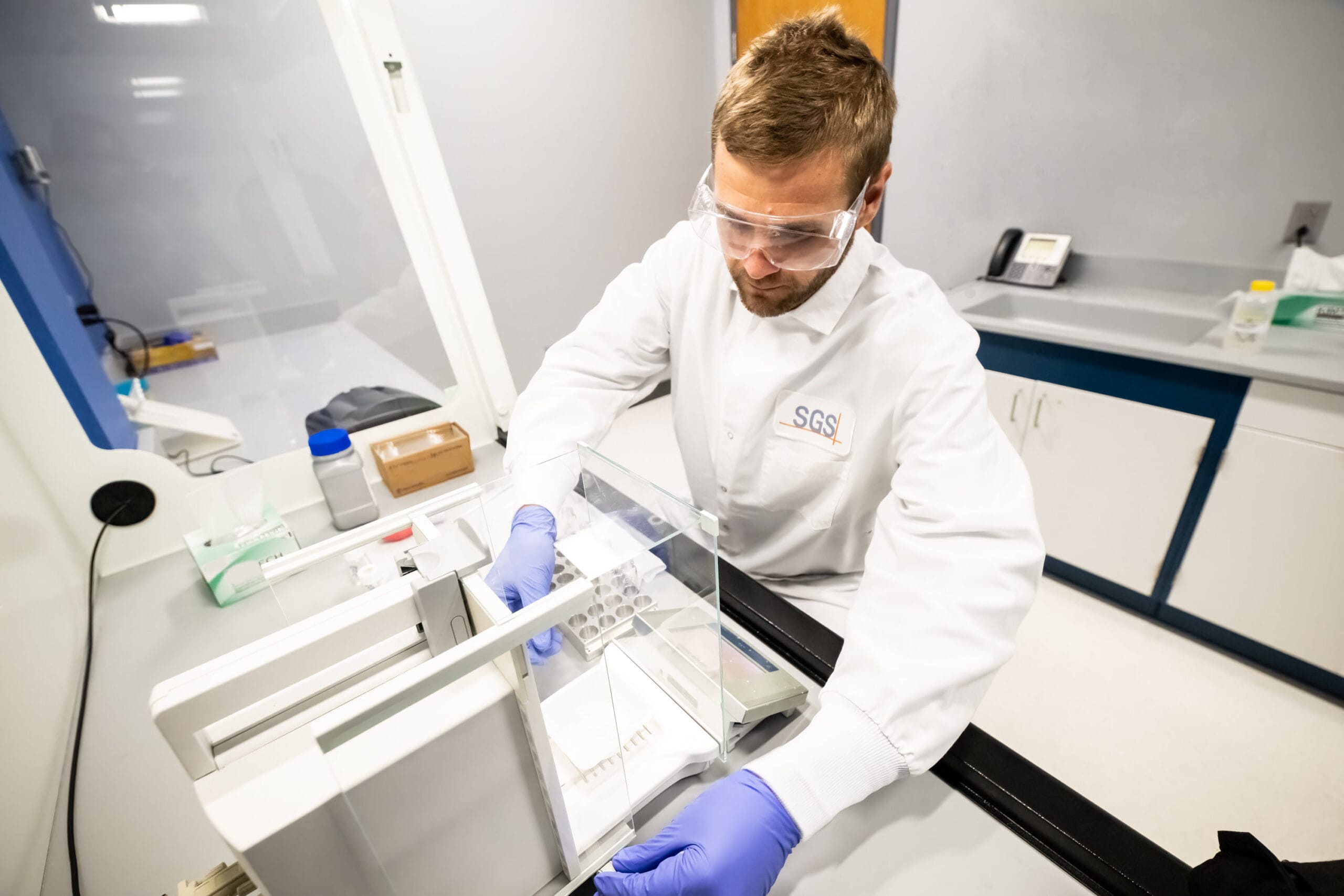

Chromatography

Headspace Gas Chromatography is used to identify and quantify volatile organic compounds (VOC’s) present in samples.

Headspace GC is a specific gas chromatography technique used to analyze volatile compounds. A sample is placed in a closed vial and incubated at elevated temperature, releasing VOC’s into the vial headspace, which is then sampled for GC analysis.

Approaches

Solid or liquid samples are sealed in glass vials. Water or a high-boiling organic solvent may be added to the vial to dissolve the sample and facilitate release of volatile compounds to the gas phase.

The sample vials are typically heated to drive partitioning of volatiles from the solid or liquid phase into the gas phase. Sample vials can be agitated during heating.

A portion of the vial headspace is usually injected directly via a heated gas-tight syringe or sample loop. If greater sensitivity is required, solid phase micro-extraction (SPME) can be used to concentrate volatiles prior to GC analysis.

Detection options for headspace GC include flame ionization detection (FID) and mass spectrometry (MS) detection. FID is often a good option for quantitation of known target compounds. MS detection allows for identification of unknown volatiles via mass spectral library searching using the NIST mass spectral library.

Sample Considerations

Virtually any sample that can be made to fit into a headspace vial can be tested. A full evaporation technique can be used for headspace analysis of volatile samples.

The required sample size for headspace GC is inversely proportional to the concentration(s) of volatile compound(s) that must be detected or quantified.

A sample size of 0.1 to 10 g is typical for headspace GC. Quantitative analysis usually requires a larger sample amount because a standard addition method is used.

Samples for quantitative headspace GC/MS should be homogeneous with respect to the concentration of volatiles.

Contact us to talk through your specific sample considerations and chromatography testing needs.

Experience

Work we’ve done:

- Identification and quantification of residual solvents in packaging materials for food contact or pharmaceutical applications

- Odor analysis in polyolefin packaging film

- Identification and quantification of volatile organic compounds (VOC’s) present in polymers used for medical implants

- Identification of compounds responsible for off-odor in post-consumer recycled carpet

- Residual solvents in pharmaceutical actives and excipients

- Quantification of residual blowing agents in polyolefin foam

- Identification of off-gas products from combustion or pyrolysis of polymers