Spectroscopy

Fourier Transform Infrared Spectroscopy (FTIR)

Infrared spectroscopy is a powerful technique widely used for polymer analysis, primarily for identification and quality assurance purposes. It is a subset of spectroscopy that uses infrared light to analyze a sample, and the resulting spectrum indicates how much energy was absorbed at various wavelengths. These absorption characteristics provide valuable insights into the molecular structure of the sample which allows us to identify unknown materials.

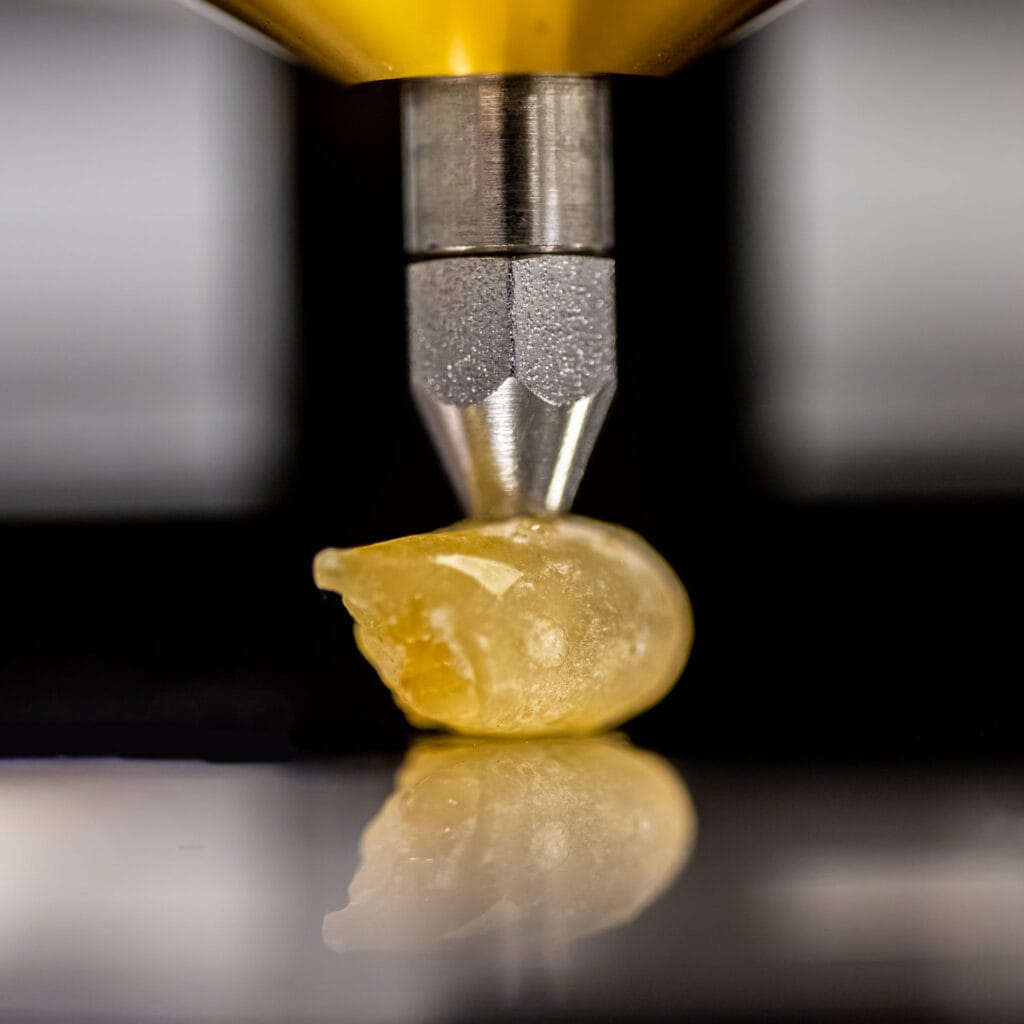

The most common technique we use is FTIR ATR, or Fourier Transform Infrared Spectroscopy with Attenuated Total Reflectance. In this method, infrared light passes through a crystal in direct contact with the sample, allowing the light to interact solely with the surface. The resulting spectrum provides information about the sample’s chemical bonds and functional groups. This approach is especially effective for analyzing solids, liquids, films, and molded parts. In most cases, it can be a non-destructive test (NDT) or requires minimal sample preparation.

Approaches

The Infrared Spectrometer provides data over the range from 4000 to 400 cm-1 with the main instrument bench and a somewhat narrower range of analysis (4000 to approximately 650 cm-1) when an attenuated total reflectance accessory is used.

Solids, powders, liquids, films, and molded parts can be evaluated directly in ATR mode and powder materials can be evaluated by preparing a KBr pellet and analyzing the sample in transmission where the incident infrared light passes through the sample.

Sample Considerations

Virtually any sample can be evaluated using the FTIR spectroscopy method of analysis, solids and liquids are most commonly evaluated. The solid materials can be thermoset or thermoplastic materials, rubber materials, coatings, fibers, and virtually any manufactured product. A contamination can be analyzed by removing it from a surface or having it transferred by contact onto the ATR crystal for analysis. Liquid samples include lubricants, solvents, , or any other liquid whose identity must be determined.

Contact an expert to talk through your specific sample considerations.

Experience

- First article inspection of goods

- Resin identification and comparison

- Contamination analysis

- Monitoring the progress of a chemical reaction

- Material certification

Products we’ve tested:

- 3D Printed Glass Filled Nylon 66

- Active Pharmaceutical Ingredients (API) following USP Monographs

- Polylactic acid plates, screws, and mesh.

Work we’ve done:

- Comparison of multiple products to assess similarities and differences

- Surface contamination analysis

- Monitoring the progress of a chemical reaction

- Thermoplastic material identification

- Rubber material identification after controlled pyrolysis