Thermal

Identifying and quantifying fillers present in a resin helps ensure the product performs as designed.

Filler material can provide important characteristics to a product. For example, titanium dioxide is commonly added to polymers as a white pigment and for its UV stabilization properties while glass fibers are commonly added for enhanced strength. Too much or too little filler can cause the product to fail and cost a manufacturer or end user both time and money. Understanding the filler content of a polymer is necessary to ensure the polymer and products they are used in perform as designed.

Approaches

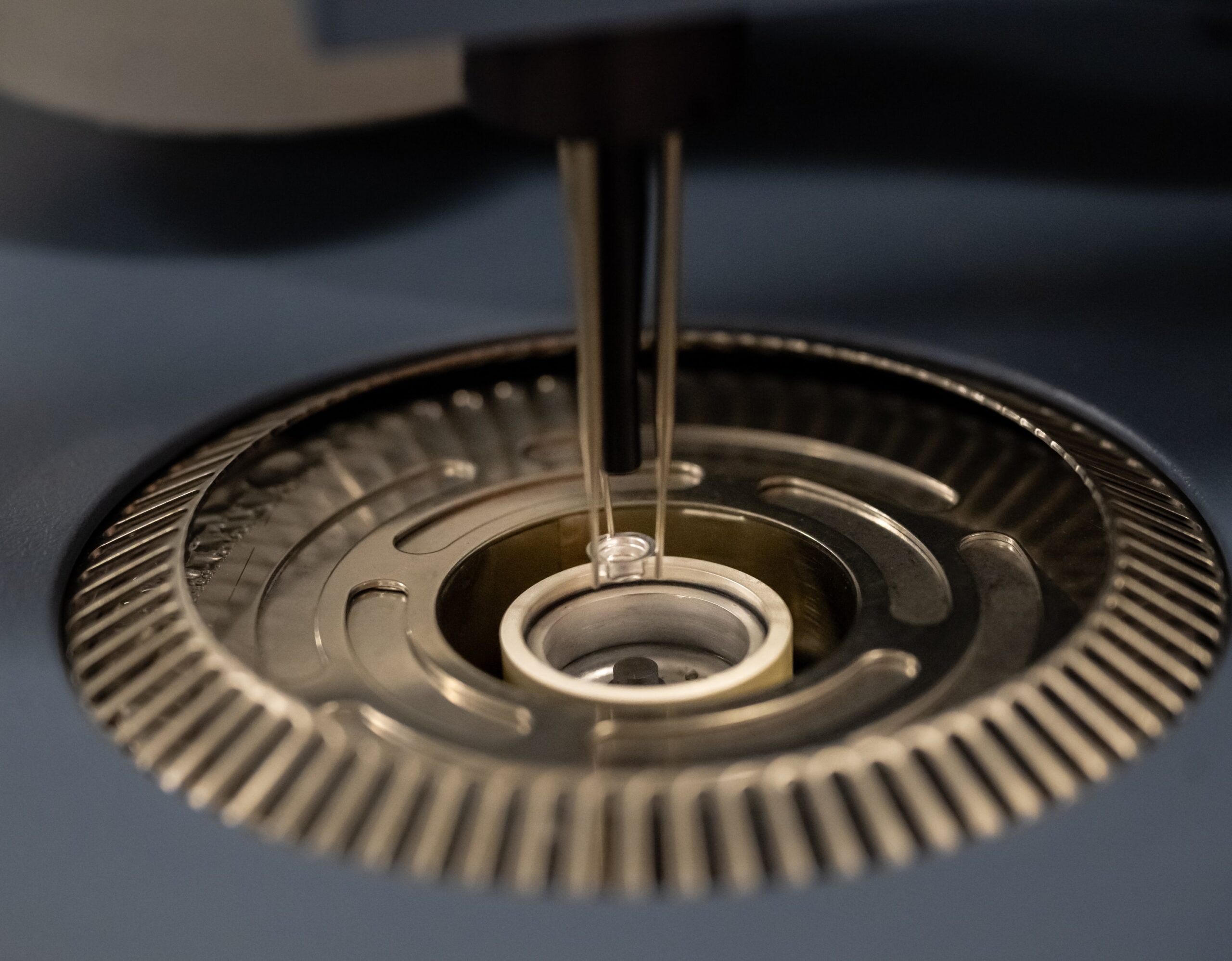

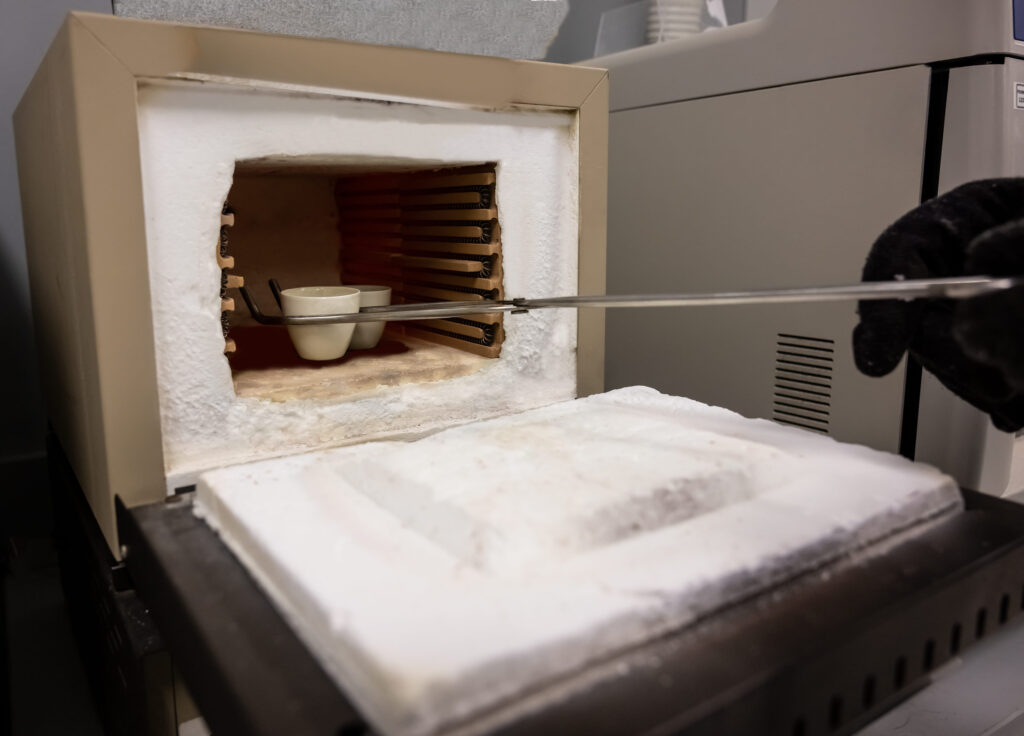

Thermogravimetric Analysis (TGA) and Ash Content are the most common techniques for determining the quantity of a filler within a polymer. For analysis by TGA, the sample is heated at a predetermined controlled rate and atmosphere to burn away all of the organic material until the inorganic filler content is all that remains. The TGA monitors the percentage of mass present throughout the range of temperatures tested relative to the initial amount of material. For Ash Content, a muffle furnace is utilized to combust the organic material and the mass of the remaining inorganic material is reported. Unlike the TGA analysis, only the initial and final sample masses are monitored but a larger sample is analyzed which can be more representative. Images and the elemental composition of the remaining inorganic material are collected by Scanning Electron Microscopy with Energy Dispersive Spectroscopy (SEM-EDS). The SEM images can provide valuable information about the morphology of the filler which often helps with identification. The elemental composition that is provided by the EDS analysis includes the additional data required to identify inorganic filler or fillers used.

Sample Considerations

Analysis by TGA requires only about 50 mg of sample while Ash Content requires a few grams of material. Dispersions of fillers or solid samples can be analyze by either TGA or Ash Content but only non-volatile solids can be analyzed by SEM/EDS. Non conductive samples will be sputter coated to prevent electronic charging to enhance high resolution imaging.

Contact and expert to talk through your specific sample considerations and Filler Content Analysis needs.

Experience

Work we’ve done:

- Mass % of filler content

- Identification of filler content

Products We’ve Tested:

- Raw Materials

- Resins and Pellets

- Dispersions

- Medical Devices

- Consumer Products

- Recycled materials