Thermal

Rheology is a thermal test method that measures the melt viscosity, creep, and stress relaxation responses of polymers as functions of time, temperature, and force.

Using Rheology testing we are able to determine the response of thermoplastics to shearing and the viscosity response over time (curing), frequency, and temperature. Rheology also provides comparative analysis of viscosity.

Approaches

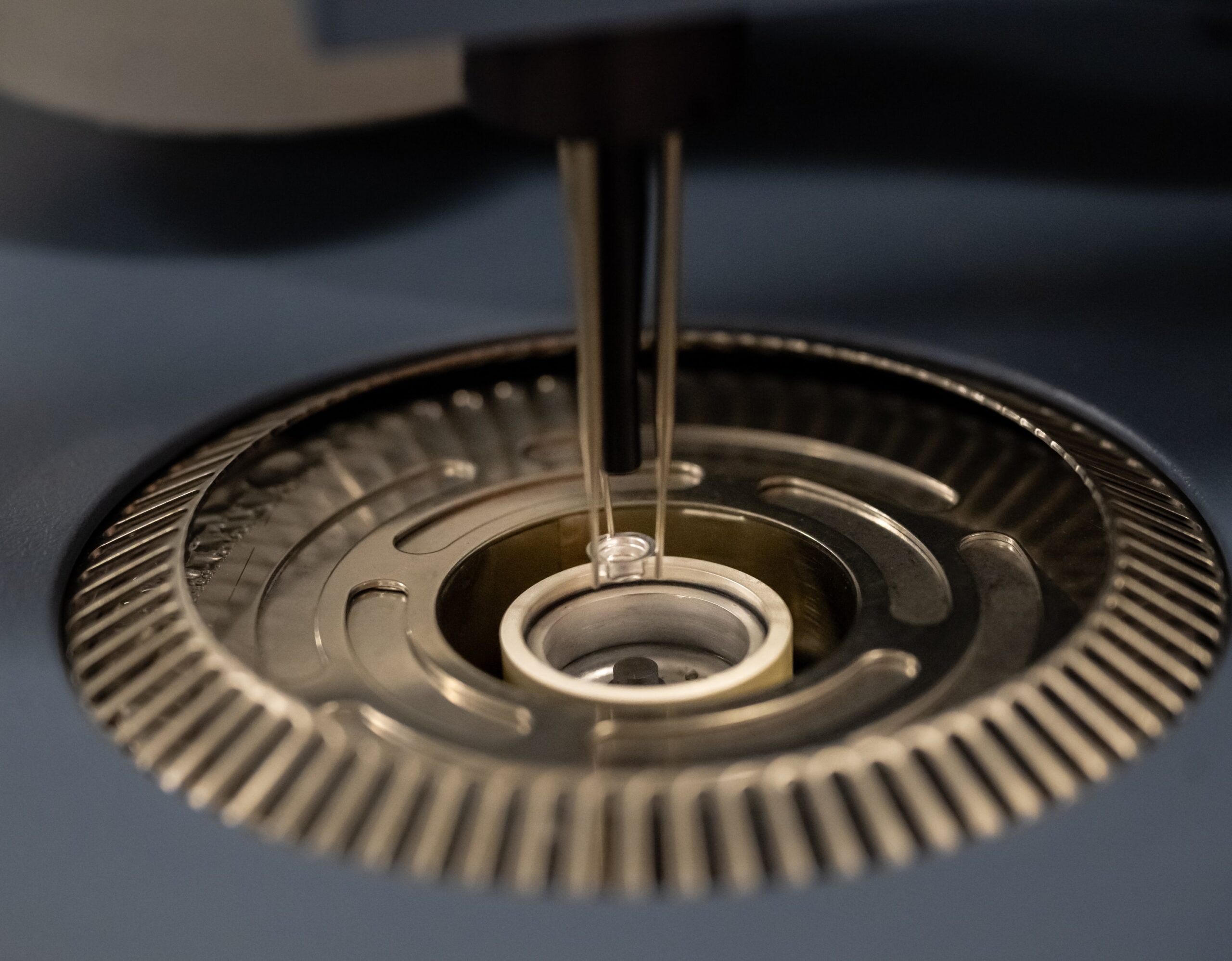

Rheology testing is conducted using parallel plate or cone-and-plate configurations from sub-ambient to high temperature. The data provided by rheology testing is more representative of processing than Melt Flow Index (MFI), a different thermal test.

ASTM D4440

Sample Considerations

Samples may be:

- Liquids

- Pastes

- Solids

Solids can be in the form of pellets, powder, or films.

We can also convert a product into a suitable sample by using our sample preparation equipment.

A typical sample volume needed for Rheology testing is a disk with dimensions of approximately 1-inch diameter and 1/8-inch in thickness.

A sample size of several hundred milliliters, a few fluid ounces, or 5-10 grams is typically sufficient.

If your sample material is in short supply don’t worry. Our scientists will work with you to ensure your sample is used in the most efficient way.

Contact us to discuss your specific Rheology Testing needs and associated sample considerations.

Experience

Products we’ve tested with Rheology include:

- Health and beauty aids, including mascara

- Construction materials, sealants, caulks, adhesives, and asphalt

- Plastic resins destined for extruded film applications

- Heat transfer fluids and lubricants

- Polymers, copolymers, and polymer blends