Physical

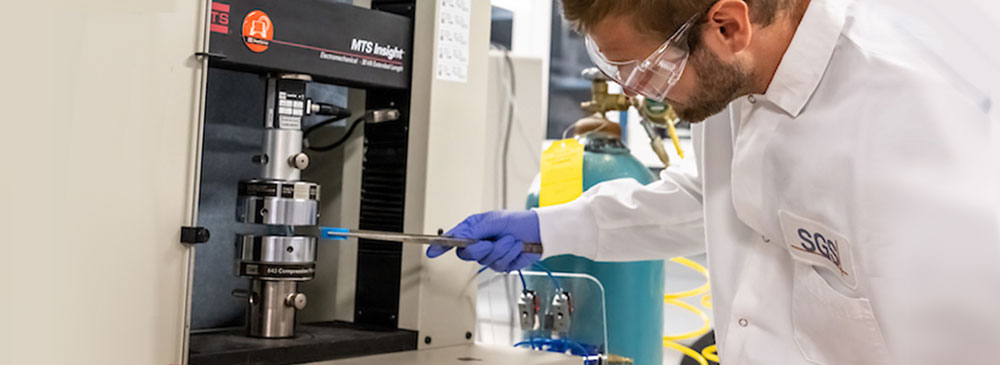

We can provide custom and validated testing fixtures, entirely based on the needs of your project.

Our team will collaborate with you to develop custom test fixtures specific to your analytical needs. We can build custom test fixtures designed by you, or our experts can design a custom test fixture for your unique situation. We can also build fixtures to comply with historic ASTM standards, for which commercial equipment is no longer available.

Approaches

Typically, we work with clients requiring non-uniform fixtures by developing testing plans to mechanically or chemically manipulate the material sample in question.

Fixture designs are conceived, drawn, and built in close collaboration with the client to test the product according to plan.

We have a machine shop on site to produce test fixtures designed to specification for custom testing capabilities. In addition, we work in collaboration with a local machine shop for larger or more complex fixtures.

Sample Considerations

We entirely customize according to your needs, therefore, there is no “typical” sample or custom fixture.

Contact and expert with your needs, we’re looking forward to the challenge!

Experience

Examples of our experience with custom test fixtures includes:

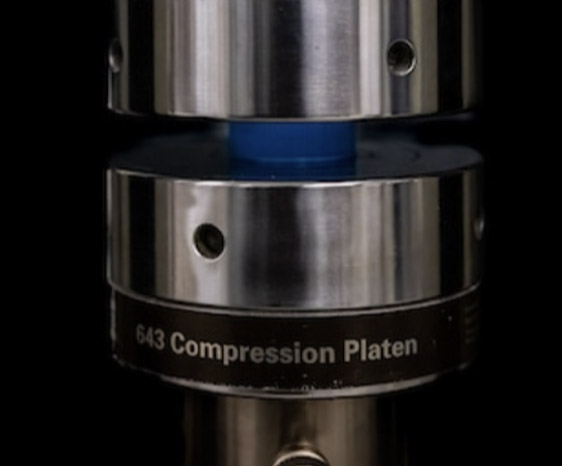

- Bioabsorbable screws tested under cyclic compressive loads at elevated temperature in saline

- Adhesive strength of multi-layer diaper components

- Documenting the performance of a motorcycle wiring harness undergoing custom chemical exposures

- Separating fluoropolymer powder with vibration apparatus based on an historic ASTM standard

- Determining the cure exotherm temperature of an unsaturated polyester resin in a rocket motor